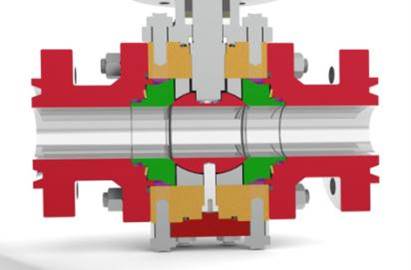

FMCVD Coating Ball Valve

> Design and Struction

- Using Pressure Seal Gasket in back side of seat, it assures stable sealing function even under low and high pressure.

- Using Disc Spring(Inconel-X750) on both sides, it always provides stable sealing function even under high-temperature.

- Moreover, it maintains tension and air tightness by using Seat Packing(VOC) to prevent fixedness of Disc Spring(Inconel-X750).

> High Temperature(550℃) Operating Cycle Test

- High Temperature(550℃) Operating

Cycle Test : Over 3,000 times.

- Seat Leak Test : No Leak

- Hardness : HRC Over 80

> Range of Size, Material

FMCVD Coating which is developed as a result of a long technical Know-how has a high durability and high strength at high temperatures. Depending on field of use, FMCVD coating is a technique with a semi-permanent life, especially Ball Valves, it can be satisfy Leakage class VI and/or over sealing quality along with the lapping technology. It boasts high durability and corrosion resistance at high temperature and high pressure fluid can be applied to harsh conditions such as slurry and catalyst

I. High-hardened Quality : Bri-Nell Hardness HV1300~1400(Rock-Well Hardness HRC 80 and over)

II. Durability & Abrasion resistance : Prevent Scratches in the high-temperature/ high-pressure and have strong corrosion resistance.

III. Smooth operation and long life due to less of friction coefficient compared with normal heat treatment materials.

IV. Excellent corrosion resistance, such as hydrochloric acid, sulfuric acid, hydrofluoric acid etc.

V. Resistance to thermal shock of high temperature up to 550℃.

FMCVD COATING METAL SEAT BALL VALVE

RANGE OF SIZE : ANSI CLASS 150/ 300/ 600/ 900/ 1500/ 2500/ 4500LB ½” – 24”

MATERIAL : FORGED CARBON, ALLOY OR STAINLESS STEEL

> Helium Leak Test(SHELL)

- LEAKAGE CLASS: Class VI

- Helium Leak Test(SHELL) : 1X10^5 std ㎤/s