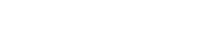

METAL SEATED BALL VALVE

> Design and Struction

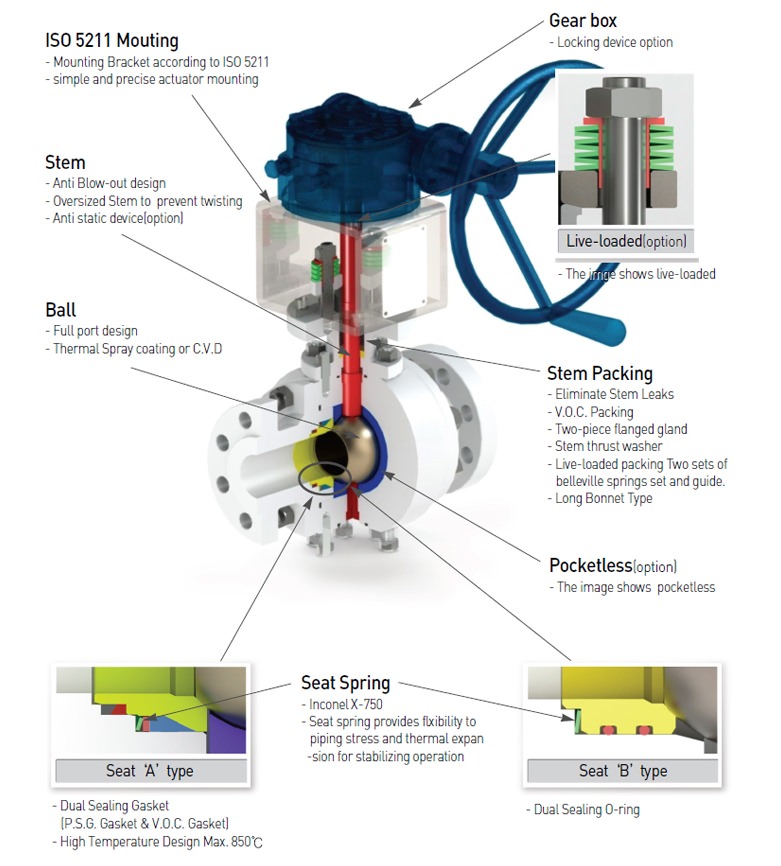

> Exploded View

| NO | Part Name | Q ty |

|---|---|---|

| 1 | Body | 1 |

| 2 | Cap | 2 |

| 3 | Satring | 2 |

| 4 | Ball | 1 |

| 5 | Bonnet | 1 |

| 6 | Stem | 1 |

| 7 | Packing | 1Set |

| 8 | Gland | 1 |

| 9 | Gland Flange | 1 |

| 10 | Pocketless | 2 |

| 11 | Seat Gasket | 2 |

| 12 | Cap Gasket | 2 |

| 13 | Bonnect Gasket | 2 |

| 14 | Thrust ring | 2 |

| 15 | Packing Ring | 1 |

| 16 | Bottom Flange | 1 |

| 18 | Trunnion | 1 |

| 20 | Gear box | 1 |

| 21 | Body Bolt & Nut | Set |

| 22 | Bonnect Bolt & Nut | Set |

| 24 | Gland Bolt & Nut | 2Set |

| 26 | Bracket Bolt | 4 |

| 27 | Bracket | 1 |

| 28 | Live loading | 2Set |

| 29 | Seat Spring | 2 |

| 30 | Live loading Guide | 2 |

| 32 | Name plate | 1 |

| 33 | Name plate bolt | 4 |

| 34 | Seat packing | 2Set |

| 35 | Seat Offset ring | 2 |

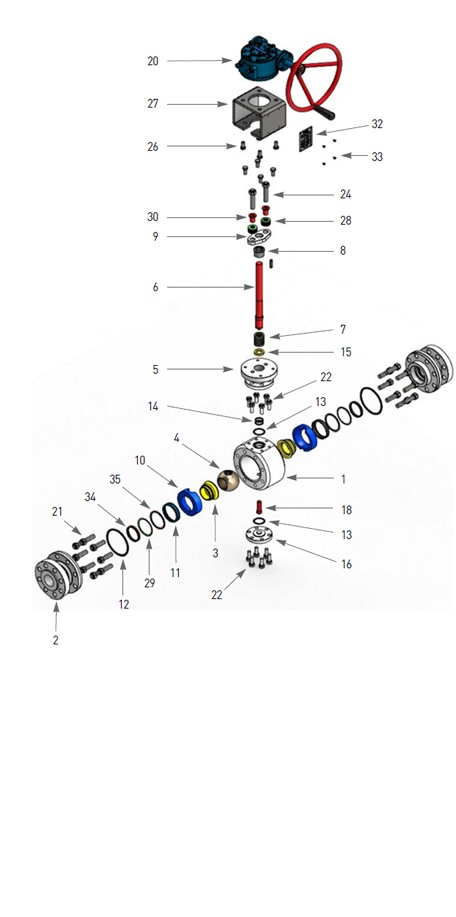

> Analysis Simulations

Finite Element Analysis (FEA) is used FMC Valve design process to predict the behavior of a valve’s components by subjecting them to varying loads. Computauional Fluid Dynamic (CFD) is used calculate the flow throuth the trim of valve. Also Used to determine the flow coefficient(v) of valves.

> On / Off Cycle Test

Cycle test conducted by applying the fluids used.

> Heating On / Off Cycle Test

Heating Cycle test conducted by applying the fluid and temperature used.