PLASTIC VALVES

Sluice Valve(Flanged)

Automatic(Pneumatic)Diaphragm Valves

Diaphragm(Flanged)

Ball Valves(Screwed)

Ball Valves(Flanged)

Union Ball Valves(Screwed)

SAFFI VALVE

● Valves with pneumatic actuators

● Kinetrol vane type actuators

● Rack & pignon actuators

● Max – AIR corrosion resistant thermoplastic actuators

● Limit switch boxes

● Manual over-ride

● Positioners

● Valves with elcetric actuators

● SAFI eletric actuators for DC 12V, 24V, 48V and AC 110V, 240V

● Corrosion resistant Thermoplastic casing IP 65 / NEMA4

● Option 1 : SM – 1 Small & Compact

● Option 1 : SM – 2 manual override and visual indicator as standard

● Option extras include : Condensate heater, Extra switch, Battery back-up unit

● Options for manual operation

● Lockable handle

● Extended stem

● Limit switch box

● Handwheel Reduction Gear

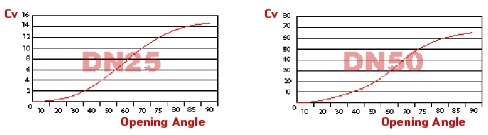

● V-Port Flow Control Valves

● Complete valve and actuator package can provied meet your flow requirement as the same timeas being corrosion and erosion resistant

● Ball Relief hole

● The ball of SAFI ball valves may be provied with a lateral hole on the up stream side, to vent the ball cavity in the closed position This is recommended to a avoid trapped pressurized fluids, and avoid accidents with chemicals witch tend to dacompose and prodce gases such as hydrogen peroxyde.

● 3 way valves

● Three-way ball valves are available up to DN100, with L-Ball, double-L or T-ball

● Silicone Free

● All SAFI products are moduled with silicone-free release agents. Furthermore, an option is available for automobile paint systems, Each component is individually cleaned following a customer-approved procedure, and the product is guaranteed free of silicones an delivered in a sealed plastic bag.

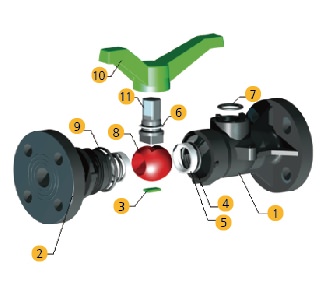

| No. | Description | Material |

|---|---|---|

| 1 | Body | GRPP/PVDF/ASPP/ASPVDF |

| 2 | Flanged end | GRPP/PVDF/ASPP/ASPVDF |

| 3 | Locking Key | EPDM/FKM/FEP Encapsulated |

| 4 | O’ring (seat) | PIFE |

| 5 | Seat | PIFE |

| 6 | Thrust Washer | PIFE |

| 7 | O’ring (body) | EPDM/FKM/FFKM |

| 8 | Ball | PP/GRPP/PVDF/ASPP/ASPVDF |

| 9 | O’ring (body) | EPDM/FKM/FEP Encapsulated |

| 10 | Handle | GRPP/ASPP |

| 11 | Stem | GRPP/PVDF with mental insert |

NEREIDS VALVE

| Valve size | L | K | Weight | |||

|---|---|---|---|---|---|---|

| DN | Inch | ANSI 150 | PN10 | ANSI 150 | ANSI 10K | (kg) |

| 80 | 3 | 48 | 160 | 152 | 150 | 1.5 |

| 100 | 4 | 54 | 180 | 190 | 175 | 2.5 |

| 125 | 5 | 56 | 215 | 210 | 3.2 | |

| 150 | 6 | 57 | 240 | 241 | 240 | 3.8 |

| 200 | 8 | 64 | 295 | 299 | 290 | 6 |

| 250 | 10 | 71 | 350 | 362 | 355 | 9.6 |

| 300 | 12 | 81 | 400 | 432 | 400 | 15 |

| 350 | 14 | 92 | 445 | 18.3 | ||

| 400 | 16 | 102 | 515 | 540 | 510 | 24.6 |

| 500 | 20 | 127 | 620 | 635 | 620 | 43.5 |

| 600 | 24 | 154 | 725 | 750 | 730 | 85 |

| 700 | 28 | 292 | 840 | 864 | 840 | 219 |

| 750 | 30 | 318 | 914 | 255 | ||

| 800 | 32 | 318 | 950 | 978 | 950 | 316 |

| 900 | 36 | 330 | 1050 | 1086 | 1050 | 409 |

| 1000 | 40 | 410 | 1160 | 1200 | 1160 | 499 |

| 1100 | 42 | 410 | 1257 | 579 | ||

| 1200 | 48 | 470 | 1380 | 1422 | 1380 | 774 |

| 1500 | 60 | 530 | 1700 | 1759 | 1700 | 1213 |

DN700 to DN2000 Flange Type

Design Pressure @ 25 ˚ : 10 bar

Leakage rate : Class VI

Maximum service temperature : 100˚C

Acluator Mounting pad : ISO5211

● Specifications for sea water and brine service

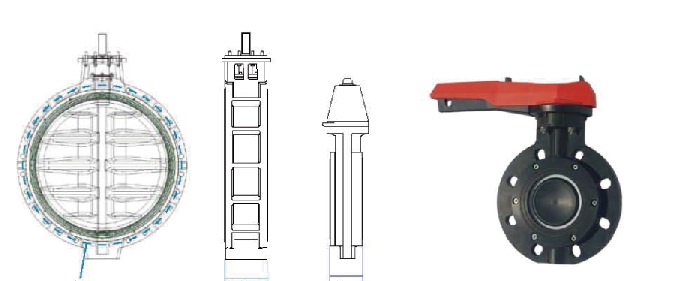

Eccentire butterfly valve

– DN80 – DN600, water type, face to face as per API 609 table 1

– DN700 to DN2000,Double Flanged type, face to face as per EN558 table13

Body Material : Telene (Dicyclopentadiene)

Disc Material : Telene DCPD

Seat : EPDM

Shaft type : One Piece, straight though shaft square section inside disc

Shaft material : Non wetted stainless steel encapsulated in DCPD

Shaft Seal : Live loaded chevron PIFE gland packing

● Specifications for critical corrosive service

Eccentire butterfly valve(API 609 categorie B)

– DN80 – DN600, water type, face to face as per API 609 table 1

– DN700 to DN2000,Double Flanged type, face to face as per EN558 table13

Body Material : Telene (Dicyclopentadiene)

Disc Material : Telene DCPD

Seat : EPDM

Shaft type : One Piece, straight though shaft square section inside disc

Shaft material : Non wetted stainless steel encapsulated in DCPD

Shaft Seal : Gland packing with PIFE chevron packing and EPDM loading